Capacitive Touch Sensor Designs, Substrates, and Stack-Ups

You are here

Capacitive touch sensors have revolutionized how we interact with technology, from smartphones and tablets to home appliances and automobiles. These sensors use the capacitance of an electric field to detect touch or proximity, offering a fast and reliable interface for users. However, designing capacitive touch sensors is not a simple process, as it requires careful consideration of factors such as substrate material, stack-up configuration, and electrode design.

Capacitive touch sensors are designed to meet specific customer needs and requirements. Various substrates and stack-ups can be chosen based on the application. Performance, weight, and cost are all considerations that can affect the sensor design.

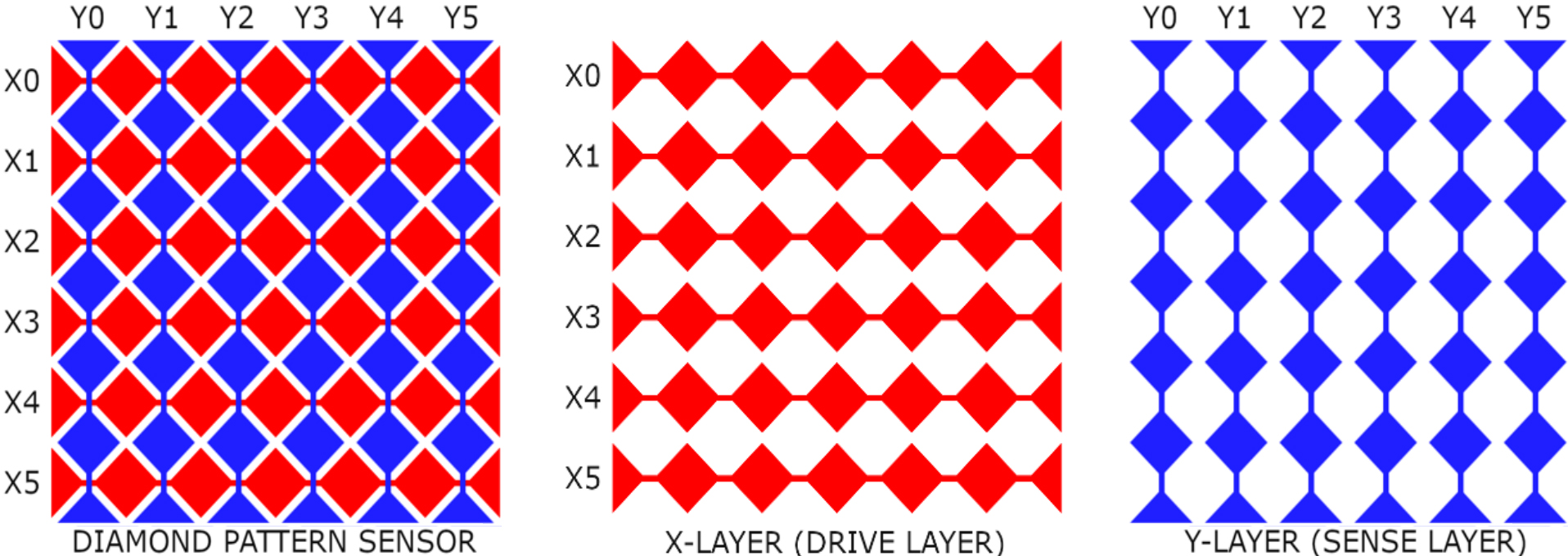

The recommended design for a multi-touch 2D touch sensor is usually an interlaced X-Y diamond ITO (Indium Tin Oxide) pattern grid. The diamond sensor pattern can support both self-capacitive and mutual capacitive touch measurements. The diamond pattern provides good resolution for touches made with bare fingers, thick gloves, and fine-tipped styli. The diamond pattern uses an uncomplicated design and offers excellent performance at a reasonable cost.

The sensor substrate on which the sensor pattern is constructed is chosen based on the project's performance requirements, mechanical design, and cost targets. Two commonly used substrates for touch sensors are glass and PET film. Glass substrates offer the advantages of thermal stability and low birefringence, which are both particularly important for automotive and industrial applications. In addition, PET film-based sensors are lighter, less expensive, and can be used in touch applications requiring a mechanically curved sensor.

The touch sensor stack-up chosen also affects the price and performance of the final touchscreen solution. There are three common stack-ups used with diamond ITO patterned sensors. They are the Single ITO Layer (SITO), Dual ITO Layer (DITO), and Two Layer sensor designs.

The SITO design patterns both X and Y electrodes on the same side of a single substrate. It uses conductive bridges of ITO or metal to allow the X and Y electrodes to cross. This design provides excellent accuracy and sensitivity.

DITO also uses a single substrate but patterns the X electrodes on one side of the substrate and the Y electrodes on the other. Placing the X and Y electrodes on opposite sides of the substrate negates the need for conductive bridges. This design provides excellent resolution at a lower cost compared to SITO designs.

The 2-layer design has the X electrodes patterned on one substrate and the Y electrodes on another. The two patterned substrates are aligned and bonded using an Optically Clear Adhesive (OCA). Vertical Separation of the X and Y electrodes affects the field strength, making selecting the substrate thickness critical.

A custom capacitive touch sensor offers numerous benefits over off-the-shelf alternatives. It can be an excellent investment for businesses or individuals looking to create a unique product or user experience. Here are some key selling points to consider:

- Tailored to your specific needs: A custom capacitive touch sensor is designed specifically for your product or application, ensuring that it meets your exact requirements in terms of size, shape, functionality, and performance.

- Enhanced functionality: A custom sensor can be optimized to offer advanced features such as multi-touch support, gesture recognition, and pressure sensitivity, enabling you to create a more intuitive and engaging user experience.

- Brand differentiation: By incorporating a custom touch sensor into your product, you can differentiate yourself from competitors and create a unique brand identity that resonates with customers.

- Reliability and durability: Custom sensors are typically designed and manufactured to the highest quality standards, ensuring reliable and durable performance even in harsh environments.

- Expert support: When you work with US Micro Products, you can benefit from the expertise of our experienced engineers, who can guide you through the design, development, and manufacturing process, helping you to optimize your sensor for maximum performance and cost-effectiveness.

In summary, a custom capacitive touch sensor can offer numerous benefits over off-the-shelf alternatives, including tailored functionality, enhanced user experience, brand differentiation, reliability, durability, and expert support. By investing in a custom sensor, you can create a product that stands out from the crowd and meets the specific needs of your customers.

If you have a project that uses any display or touch technology, US Micro Products can provide a solution designed for your application. Send us an email at sales@usmicroproducts.com.